Key Insights

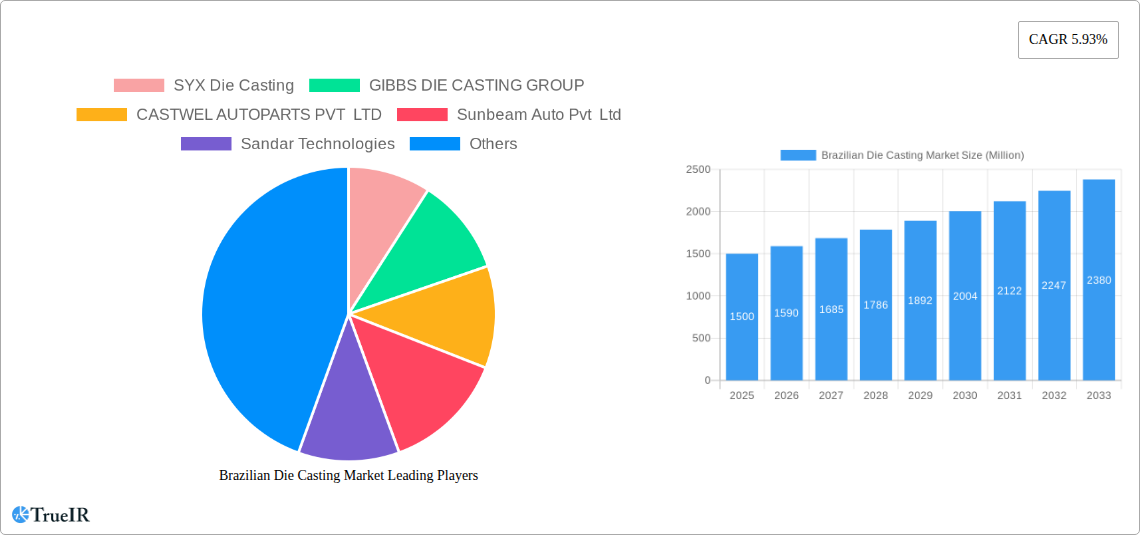

The Brazilian die casting market is poised for significant expansion, projected to reach a substantial market size of approximately $1,500 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of 5.93% anticipated through 2033. This growth trajectory is primarily fueled by the burgeoning automotive sector, a key consumer of die-cast components for applications such as engine parts, body assemblies, and transmission systems. The increasing demand for lightweight yet durable automotive parts to improve fuel efficiency and meet stringent environmental regulations is a significant driver. Furthermore, advancements in die casting technologies, including vacuum die casting and semi-solid die casting, are enhancing production efficiency, component quality, and enabling the creation of more complex geometries, further bolstering market demand. The expanding industrial base beyond automotive, encompassing sectors like aerospace, electrical and electronics, and consumer goods, also contributes to this positive outlook, creating diverse application avenues for die-cast products.

Brazilian Die Casting Market Market Size (In Billion)

Despite the promising growth, the Brazilian die casting market faces certain restraints. Fluctuations in raw material prices, particularly aluminum and zinc, can impact production costs and profit margins for manufacturers. Economic volatility and political uncertainties within Brazil could also influence investment decisions and consumer spending, indirectly affecting demand for die-cast products. Moreover, the availability of skilled labor for operating advanced die casting machinery and maintaining quality standards presents a potential challenge. However, the market is actively addressing these by investing in automation and training programs. Key players like SYX Die Casting, GIBBS DIE CASTING GROUP, and Endurance Technologies Ltd. are strategically expanding their capacities and innovating their product offerings to capitalize on the evolving market landscape and maintain a competitive edge in this dynamic sector.

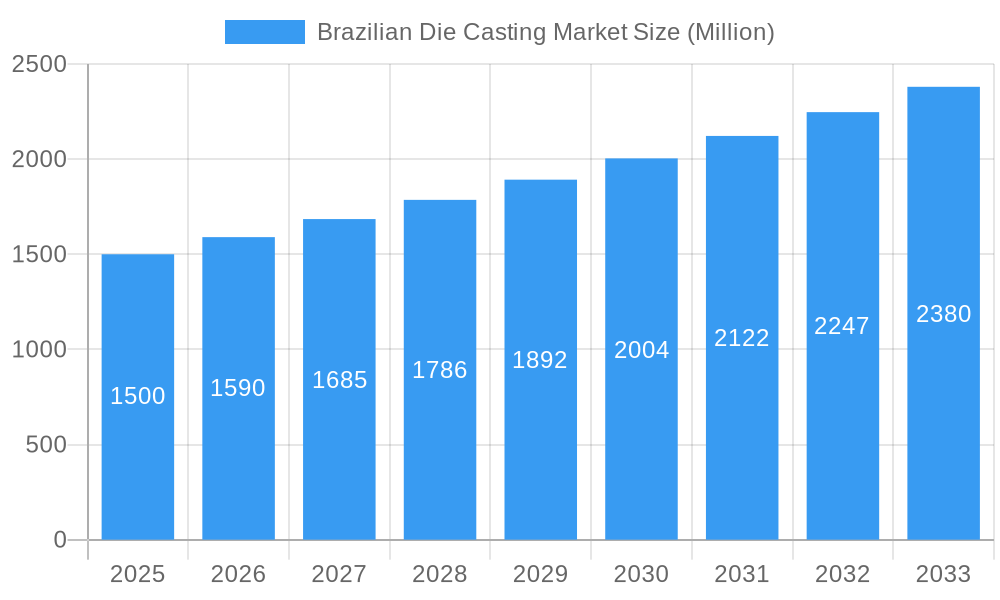

Brazilian Die Casting Market Company Market Share

This in-depth report offers a definitive exploration of the Brazilian Die Casting Market, meticulously analyzing its current state and projecting its future trajectory through 2033. Delving into intricate market dynamics, technological advancements, and competitive strategies, this research provides invaluable insights for stakeholders seeking to capitalize on the burgeoning opportunities within Brazil's vital manufacturing sector. With a focus on die casting Brazil, aluminum die casting Brazil, and automotive die casting Brazil, this report is an essential resource for understanding market segmentation, growth drivers, and competitive landscapes. The study encompasses a comprehensive historical period (2019-2024), a crucial base year (2025), and an extensive forecast period (2025-2033), offering a robust outlook on market evolution.

Brazilian Die Casting Market Market Structure & Competitive Landscape

The Brazilian Die Casting Market exhibits a moderately concentrated structure, with a mix of established global players and emerging domestic manufacturers vying for market share. Innovation remains a key differentiator, driven by the increasing demand for lightweight and high-performance components across various industries. Regulatory impacts, particularly those pertaining to environmental sustainability and safety standards, are shaping production processes and material choices. The market is also influenced by the availability and cost-effectiveness of product substitutes, such as machined parts or plastic components, though the superior strength and precision of die-cast parts often provide a competitive advantage. End-user segmentation reveals a strong reliance on the automotive industry, followed by electrical and electronics, and industrial machinery. Mergers and acquisitions (M&A) are expected to play a significant role in market consolidation, with recent trends indicating strategic alliances aimed at expanding production capacities and technological expertise. Quantitative analysis suggests a concentration ratio of approximately 55% among the top five players by revenue in 2025. M&A activities in the historical period (2019-2024) amounted to an estimated USD 300 Million, signaling increasing industry consolidation.

Brazilian Die Casting Market Market Trends & Opportunities

The Brazilian Die Casting Market is poised for significant expansion, fueled by a confluence of robust economic recovery, increasing industrial output, and a growing emphasis on sophisticated manufacturing techniques. The market size is projected to experience a Compound Annual Growth Rate (CAGR) of approximately 6.8% from 2025 to 2033, reaching an estimated value of USD 8,500 Million by the end of the forecast period. This growth is underpinned by substantial technological shifts, with a notable rise in the adoption of advanced die casting processes such as vacuum die casting and semi-solid die casting, which offer enhanced material properties and reduced porosity. Consumer preferences are increasingly leaning towards products that are lighter, more durable, and manufactured with greater precision, directly benefiting the die casting sector. The automotive industry, a cornerstone of the Brazilian economy, continues to be a primary demand driver, with manufacturers seeking innovative solutions for engine parts, transmission components, and body assemblies to meet stringent fuel efficiency and performance standards. The increasing penetration of electric vehicles (EVs) also presents a unique opportunity, as EV manufacturers require specialized, lightweight components. Furthermore, government initiatives promoting industrial development and foreign direct investment are creating a fertile ground for market growth. The competitive dynamics are evolving, with companies focusing on vertical integration, advanced tooling, and sustainable manufacturing practices to gain a competitive edge. The market penetration rate for advanced die casting technologies is expected to reach 70% by 2033. Opportunities also lie in expanding applications beyond the traditional automotive sector, including aerospace, medical devices, and consumer durables, where the precision and cost-effectiveness of die casting can offer significant advantages.

Dominant Markets & Segments in Brazilian Die Casting Market

Pressure Die Casting stands as the dominant production process within the Brazilian Die Casting Market, accounting for an estimated 80% of the total market volume in 2025. Its widespread adoption is attributed to its efficiency, high production rates, and cost-effectiveness for mass production of intricate metal parts.

- Key Growth Drivers for Pressure Die Casting:

- High demand from the automotive sector for engine blocks, transmission housings, and chassis components.

- Established infrastructure and expertise within Brazil for this mature technology.

- Cost-competitiveness in producing large volumes of identical parts.

Body Assembly represents the leading application segment, driven by the automotive industry's continuous need for lighter, stronger, and more complex structural components to enhance vehicle safety and fuel efficiency.

- Detailed Analysis of Body Assembly Dominance: The trend towards unibody construction and the integration of advanced driver-assistance systems (ADAS) necessitate the use of precisely engineered die-cast parts for structural integrity and component integration. The increasing focus on lightweighting in passenger vehicles directly translates to higher demand for aluminum and magnesium die-cast body components. For instance, the adoption of large die-casting machines for integrated components, as seen in the Ningbo Tuopu Group's development, signifies a global trend that is influencing Brazilian manufacturers to invest in similar capabilities for enhanced structural designs. This segment is projected to grow at a CAGR of 7.2% during the forecast period.

Engine Parts also hold a significant share, driven by the ongoing demand for internal combustion engines alongside the transition to hybrid powertrains. The need for precision and durability in components like cylinder heads, engine blocks, and intake manifolds ensures sustained demand.

Transmission Parts represent another critical application, with the complexity and precision required for gears, housings, and other intricate components making die casting an ideal manufacturing process.

Others encompasses emerging applications in sectors such as electrical and electronics (e.g., enclosures, connectors), industrial machinery, and consumer goods, which are gradually gaining traction and contributing to market diversification.

Brazilian Die Casting Market Product Analysis

The Brazilian Die Casting Market is characterized by a strong focus on producing highly precise and durable metal components, primarily from aluminum and its alloys, but with increasing interest in magnesium and zinc for specific applications. Product innovations are centered around achieving greater design complexity, enhanced material properties like strength-to-weight ratios, and improved surface finishes, thereby reducing the need for secondary machining processes. Competitive advantages are derived from advanced tooling technologies, sophisticated simulation software for mold design, and efficient casting processes that minimize defects and optimize cycle times. The market is witnessing a push towards greener manufacturing practices, with a growing emphasis on recycling and the use of sustainable materials.

Key Drivers, Barriers & Challenges in Brazilian Die Casting Market

Key Drivers: The Brazilian Die Casting Market is propelled by several key factors. Technologically, advancements in automation and intelligent casting systems are enhancing precision and efficiency. Economically, the recovery and growth of the automotive sector, coupled with increasing demand from other manufacturing industries, are significant drivers. Policy-wise, government incentives aimed at boosting industrial production and attracting foreign investment create a favorable environment for expansion. The growing global trend towards lightweighting in vehicles to improve fuel efficiency and reduce emissions directly translates to increased demand for aluminum and magnesium die-cast parts in Brazil.

Barriers & Challenges: Despite the positive outlook, the market faces several challenges. Supply chain volatility, particularly concerning the availability and pricing of raw materials like aluminum, can impact production costs and lead times. Regulatory hurdles, while generally aimed at improving standards, can sometimes introduce complexities in compliance. Competitive pressures from both domestic and international players, especially those with lower production costs, can affect profit margins. Furthermore, the initial capital investment required for advanced die casting machinery and tooling can be a significant barrier for smaller manufacturers. The adoption of sophisticated automation and Industry 4.0 technologies also requires a skilled workforce, which can be a constraint. The fluctuating exchange rates in Brazil can also pose challenges for importing specialized equipment and exporting finished goods.

Growth Drivers in the Brazilian Die Casting Market Market

The growth trajectory of the Brazilian Die Casting Market is significantly influenced by technological advancements in automation and intelligent casting systems, leading to enhanced precision and operational efficiency. The robust recovery and expansion of the automotive sector, a key consumer of die-cast components for both traditional and electric vehicles, is a primary economic driver. Government initiatives aimed at promoting industrialization, supporting local manufacturing, and attracting foreign direct investment create a conducive policy environment for market expansion. The increasing global demand for lightweighting solutions in transportation, aerospace, and other industries further fuels the demand for high-performance aluminum and magnesium die-cast parts.

Challenges Impacting Brazilian Die Casting Market Growth

The Brazilian Die Casting Market faces several impactful challenges. Supply chain disruptions and price volatility of raw materials, particularly aluminum, can significantly affect production costs and profitability. Navigating complex regulatory landscapes and ensuring compliance with evolving environmental and safety standards can introduce operational complexities. Intense competitive pressures from both established global players and emerging low-cost manufacturers necessitate continuous innovation and cost optimization. The substantial initial capital investment required for advanced die casting equipment and tooling can act as a barrier to entry and expansion for many companies. Moreover, the availability of a skilled workforce proficient in operating and maintaining modern die casting technologies remains a critical concern.

Key Players Shaping the Brazilian Die Casting Market Market

- SYX Die Casting

- GIBBS DIE CASTING GROUP

- CASTWEL AUTOPARTS PVT LTD

- Sunbeam Auto Pvt Ltd

- Sandar Technologies

- Amtek Group

- ECO Die Castings

- Endurance Technologies Ltd

- ALUMINIUM DIE CASTING (CHINA) LTD

- Dynacast Inc

Significant Brazilian Die Casting Market Industry Milestones

- March 2022: Ningbo Tuopu Group Co. Ltd (Tuopu Group) announced the successful roll-off of an integrated, huge die-casting rear cabin, developed using a 7,200-ton giant die-casting machine, from its Hangzhou Bay plant in Ningbo. This development highlights advancements in large-scale die casting capabilities and their potential application in vehicle manufacturing.

- January 2022: South32, in collaboration with its joint venture partner Alcoa, announced the recommencement of production at the Alumar aluminum smelter in Brazil, utilizing 100% renewable energy. This initiative, involving a total investment of USD 175 million to restart operations at the smelter known as Brazil Aluminium, as reported by the Australian Financial Review (AFR), signals a growing commitment to sustainable energy sources within Brazil's aluminum industry, which is a critical raw material supplier for the die casting sector.

Future Outlook for Brazilian Die Casting Market Market

The future outlook for the Brazilian Die Casting Market is exceptionally positive, driven by sustained demand from the automotive sector, increasing adoption of lightweight materials, and the burgeoning use of advanced manufacturing technologies. Strategic opportunities lie in expanding into high-growth application areas such as renewable energy components, aerospace parts, and sophisticated consumer electronics. Investments in research and development for innovative alloys and sustainable casting processes will be crucial for maintaining a competitive edge. Furthermore, the ongoing trend towards nearshoring and reshoring manufacturing activities presents a significant opportunity for Brazilian die casters to capture a larger share of regional and global markets. The market is expected to witness further consolidation and technological advancements, paving the way for a dynamic and growth-oriented future.

Brazilian Die Casting Market Segmentation

-

1. Production Process Type

- 1.1. Pressure Die Casting

- 1.2. Vacuum Die Casting

- 1.3. Squeeze Die Casting

- 1.4. Semi-Solid Die Casting

-

2. Application Type

- 2.1. Body Assembly

- 2.2. Engine Parts

- 2.3. Transmission Parts

- 2.4. Others

Brazilian Die Casting Market Segmentation By Geography

- 1. Brazil

Brazilian Die Casting Market Regional Market Share

Geographic Coverage of Brazilian Die Casting Market

Brazilian Die Casting Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.93% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasingly Focused On Reducing Vehicle Weight To Improve Fuel Efficiency; Cost-effectiveness

- 3.3. Market Restrains

- 3.3.1. Competitiveness Of Alternative Materials

- 3.4. Market Trends

- 3.4.1. Rising Demand for Pressure Die Casting in Automobiles

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Brazilian Die Casting Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 5.1.1. Pressure Die Casting

- 5.1.2. Vacuum Die Casting

- 5.1.3. Squeeze Die Casting

- 5.1.4. Semi-Solid Die Casting

- 5.2. Market Analysis, Insights and Forecast - by Application Type

- 5.2.1. Body Assembly

- 5.2.2. Engine Parts

- 5.2.3. Transmission Parts

- 5.2.4. Others

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Brazil

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 SYX Die Casting

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 GIBBS DIE CASTING GROUP

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 CASTWEL AUTOPARTS PVT LTD

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Sunbeam Auto Pvt Ltd

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Sandar Technologies

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Amtek Group

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 ECO Die Castings

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Endurance Technologies Ltd

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 ALUMINIUM DIE CASTING (CHINA) LTD

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Dynacast Inc

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.1 SYX Die Casting

List of Figures

- Figure 1: Brazilian Die Casting Market Revenue Breakdown (Million, %) by Product 2025 & 2033

- Figure 2: Brazilian Die Casting Market Share (%) by Company 2025

List of Tables

- Table 1: Brazilian Die Casting Market Revenue Million Forecast, by Production Process Type 2020 & 2033

- Table 2: Brazilian Die Casting Market Revenue Million Forecast, by Application Type 2020 & 2033

- Table 3: Brazilian Die Casting Market Revenue Million Forecast, by Region 2020 & 2033

- Table 4: Brazilian Die Casting Market Revenue Million Forecast, by Production Process Type 2020 & 2033

- Table 5: Brazilian Die Casting Market Revenue Million Forecast, by Application Type 2020 & 2033

- Table 6: Brazilian Die Casting Market Revenue Million Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Brazilian Die Casting Market?

The projected CAGR is approximately 5.93%.

2. Which companies are prominent players in the Brazilian Die Casting Market?

Key companies in the market include SYX Die Casting, GIBBS DIE CASTING GROUP, CASTWEL AUTOPARTS PVT LTD, Sunbeam Auto Pvt Ltd, Sandar Technologies, Amtek Group, ECO Die Castings, Endurance Technologies Ltd, ALUMINIUM DIE CASTING (CHINA) LTD, Dynacast Inc.

3. What are the main segments of the Brazilian Die Casting Market?

The market segments include Production Process Type, Application Type.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

Increasingly Focused On Reducing Vehicle Weight To Improve Fuel Efficiency; Cost-effectiveness.

6. What are the notable trends driving market growth?

Rising Demand for Pressure Die Casting in Automobiles.

7. Are there any restraints impacting market growth?

Competitiveness Of Alternative Materials.

8. Can you provide examples of recent developments in the market?

March 2022: Ningbo Tuopu Group Co. Ltd (Tuopu Group) announced that the integrated huge die-casting rear cabin that is developed based on the 7,200-ton giant die-casting machine rolled off the assembly line at the Hangzhou Bay plant in Ningbo.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Brazilian Die Casting Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Brazilian Die Casting Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Brazilian Die Casting Market?

To stay informed about further developments, trends, and reports in the Brazilian Die Casting Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

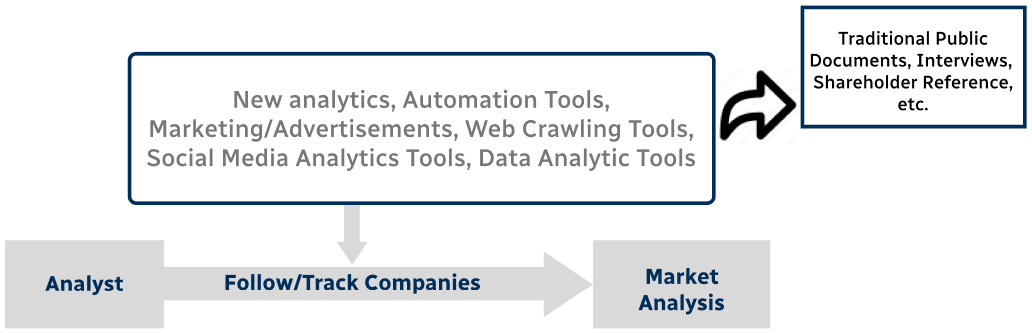

Methodology

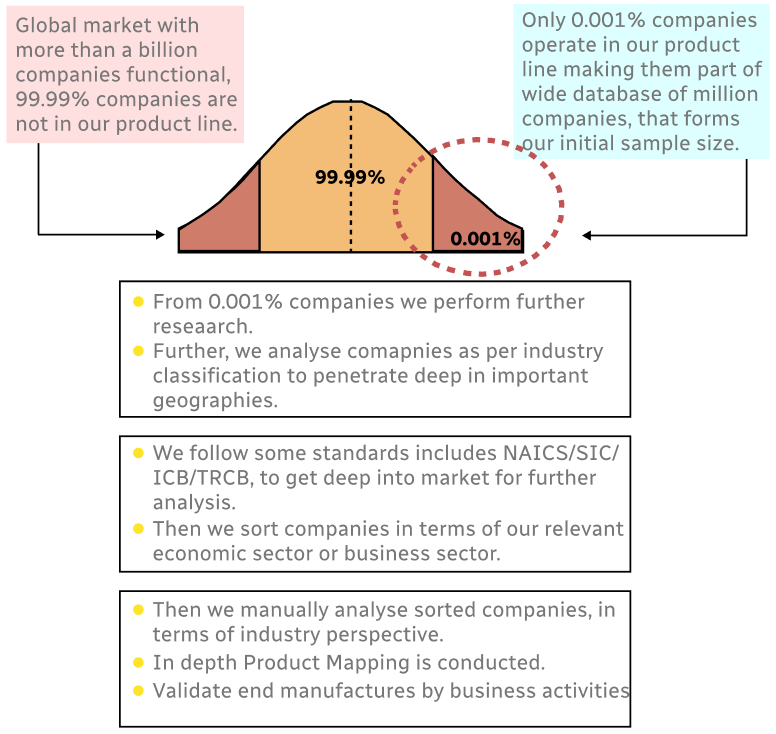

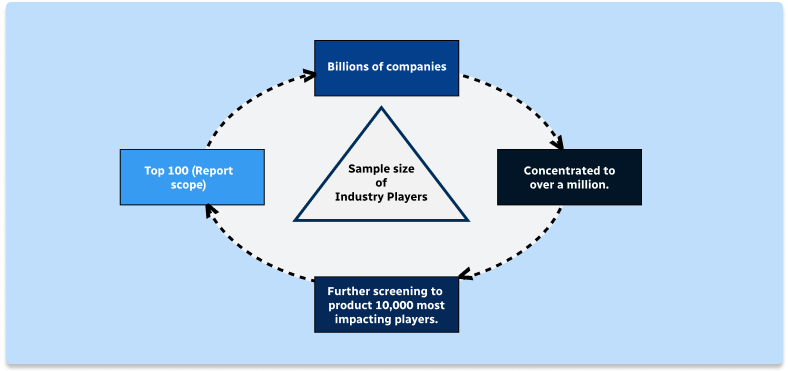

Step 1 - Identification of Relevant Samples Size from Population Database

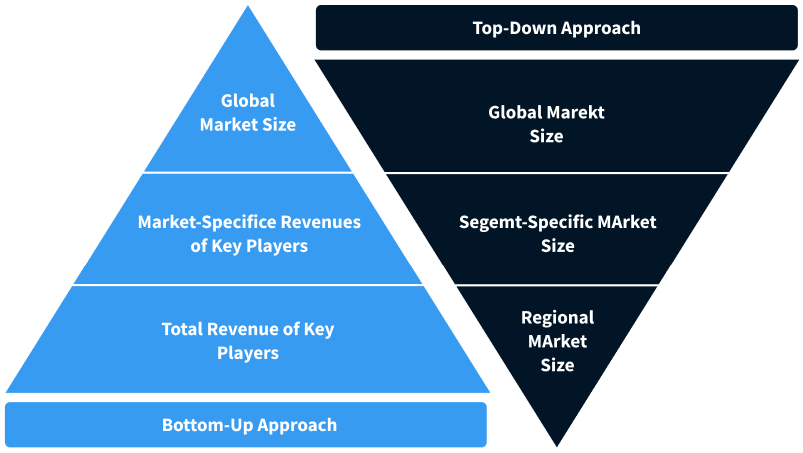

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence