Key Insights

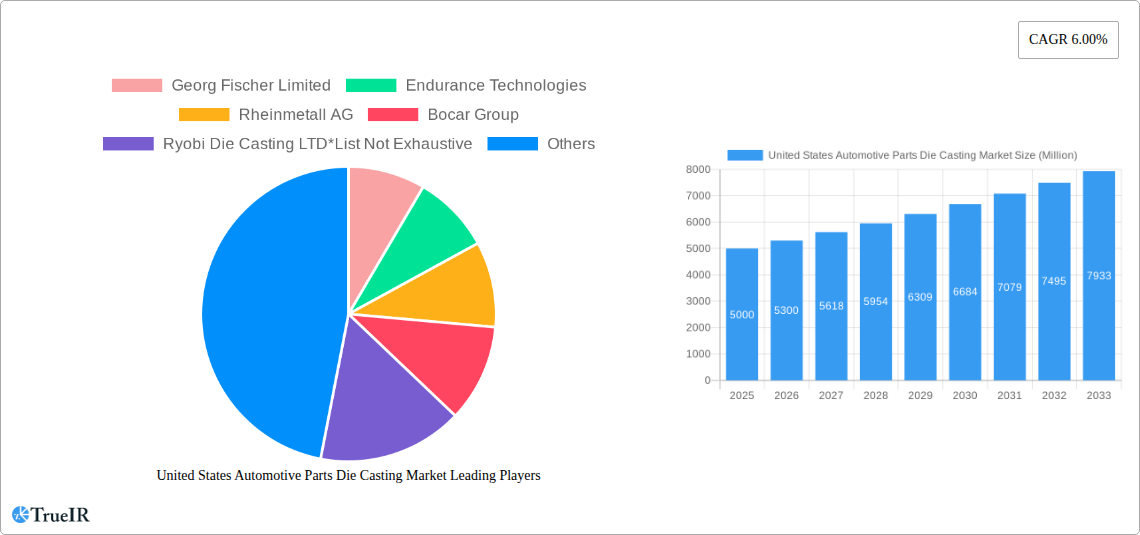

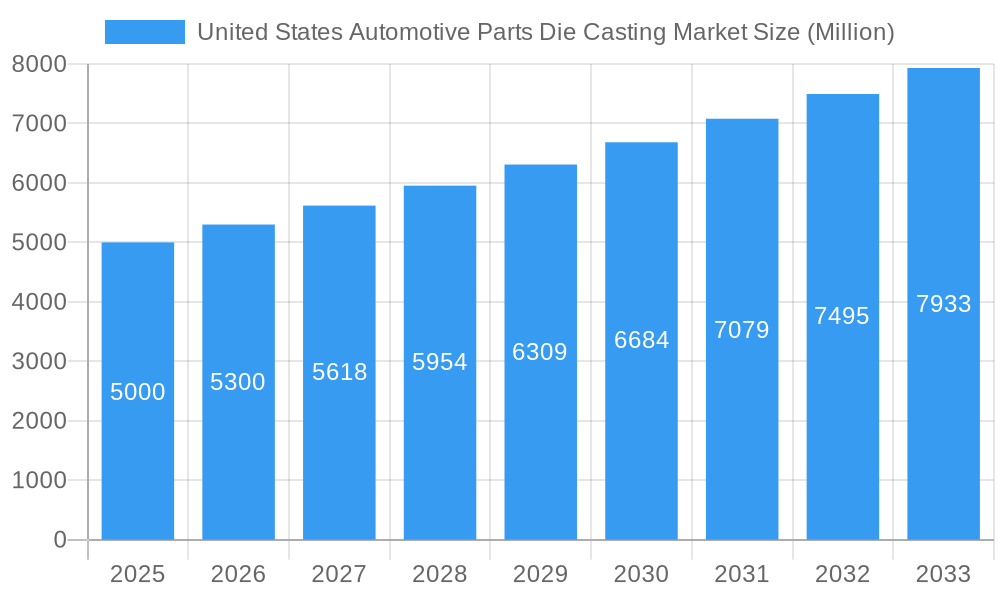

The United States automotive parts die casting market is poised for significant expansion, propelled by the escalating demand for lightweight vehicles and the rapid integration of electric vehicles (EVs). Projections indicate a robust Compound Annual Growth Rate (CAGR) of 4.7% from 2025 to 2033, building upon a strong historical performance. Key growth catalysts include the automotive sector's unwavering commitment to enhancing fuel efficiency and reducing emissions, driving the adoption of aluminum and magnesium die castings for critical components such as engine parts, chassis elements, and body panels. Innovations in die casting methodologies, including high-pressure and vacuum die casting, are enabling the production of increasingly intricate and precise automotive components, further stimulating market growth.

United States Automotive Parts Die Casting Market Market Size (In Billion)

The market exhibits a strong preference for aluminum die castings, attributed to their inherent lightweight properties and superior corrosion resistance. While pressure die casting currently holds the dominant share within the process segment, vacuum die casting is anticipated to gain traction due to its capacity for producing higher-quality, defect-reduced castings. Leading industry participants, including Georg Fischer Limited, Endurance Technologies, and Nemak, are making substantial investments in research and development to refine their product portfolios and bolster their market presence. Continued competitive dynamics and technological advancements are expected to shape the market's future trajectory.

United States Automotive Parts Die Casting Market Company Market Share

Despite a positive growth outlook, the market encounters certain headwinds. Volatility in raw material pricing, particularly for aluminum and magnesium, presents a challenge to profit margins. Moreover, the growing complexity of automotive designs and the demand for ultra-precision castings necessitate considerable capital expenditure in advanced manufacturing infrastructure and specialized workforce development. Nevertheless, long-term growth prospects remain exceptionally strong, primarily driven by the sustained demand for lighter vehicles and the burgeoning electric vehicle market. The transition to EVs offers a substantial opportunity for die casting manufacturers, as these vehicles require a high volume of lightweight, precisely engineered components. This specific market segment is forecasted to experience accelerated growth over the next decade. The US automotive die casting market is estimated to reach a size of 3580.4 million by 2025, reflecting the substantial contribution of the domestic automotive industry.

United States Automotive Parts Die Casting Market: A Comprehensive Report (2019-2033)

This dynamic report provides a detailed analysis of the United States automotive parts die casting market, offering invaluable insights for stakeholders across the value chain. The study covers the period from 2019 to 2033, with 2025 serving as the base and estimated year. We delve into market segmentation, competitive dynamics, growth drivers, and future projections, providing a complete picture of this crucial industry. The report leverages extensive primary and secondary research to deliver actionable intelligence for strategic decision-making.

United States Automotive Parts Die Casting Market Market Structure & Competitive Landscape

The US automotive parts die casting market exhibits a moderately concentrated structure, with a few major players commanding significant market share. The Herfindahl-Hirschman Index (HHI) is estimated at xx in 2025, suggesting a competitive landscape with both established players and emerging entrants. Innovation in die casting technologies, particularly in lightweight materials and automation, plays a critical role in shaping the competitive landscape. Stringent regulatory requirements concerning emissions and material usage necessitate significant R&D investments, driving consolidation through mergers and acquisitions (M&A). The observed M&A activity between 2019 and 2024 involved approximately xx deals, primarily focused on expanding geographical reach and technological capabilities. Product substitution remains a challenge, with alternative manufacturing processes like forging and plastic injection molding competing for market share. The end-user segment is primarily dominated by automotive original equipment manufacturers (OEMs) and Tier 1 suppliers, with a growing demand for lightweight and high-strength components.

- Market Concentration: HHI estimated at xx in 2025.

- Innovation Drivers: Lightweight materials, automation, and process optimization.

- Regulatory Impacts: Stringent emission and material standards.

- Product Substitutes: Forging, plastic injection molding.

- End-User Segmentation: Automotive OEMs and Tier 1 suppliers.

- M&A Trends: Approximately xx deals between 2019 and 2024, focusing on expansion and technological capabilities.

United States Automotive Parts Die Casting Market Market Trends & Opportunities

The US automotive parts die casting market is projected to experience significant growth, with a Compound Annual Growth Rate (CAGR) of xx% during the forecast period (2025-2033). This growth is fueled by the increasing demand for lightweight vehicles to enhance fuel efficiency and reduce emissions, aligning with global sustainability initiatives. Technological advancements in die casting processes, such as high-pressure die casting and robotic automation, are further boosting efficiency and reducing production costs. Consumer preferences for advanced features and enhanced vehicle performance are also driving demand for complex and high-precision die-cast components. The market is witnessing an increase in the adoption of electric vehicles (EVs), creating opportunities for die casters specializing in lightweight materials like aluminum and magnesium. Intense competition necessitates continuous innovation and strategic partnerships to maintain a competitive edge. Market penetration rates for advanced die casting technologies are expected to rise from xx% in 2025 to xx% by 2033.

Dominant Markets & Segments in United States Automotive Parts Die Casting Market

The Midwest region of the United States is currently the dominant market for automotive parts die casting, driven by a high concentration of automotive manufacturing facilities. Within the segments, pressure die casting holds the largest market share, owing to its cost-effectiveness and versatility. Aluminum remains the most widely used raw material due to its lightweight properties and excellent castability.

- By Process:

- Pressure Die Casting: Dominant segment due to cost-effectiveness and versatility. Key growth drivers include increased automation and advancements in mold technology.

- Vacuum Die Casting: Growing segment driven by demand for improved surface finish and dimensional accuracy.

- Squeeze Die Casting: Niche segment with applications in high-strength components.

- Others: Includes specialized processes like thixocasting.

- By Raw Material:

- Aluminum: Dominant raw material due to its lightweight properties and castability. Key growth drivers include the increasing demand for lightweight vehicles.

- Magnesium: Growing segment, driven by its even lighter weight compared to aluminum, but challenges remain concerning its cost and recyclability.

- Zinc: Niche segment, primarily used for smaller, less demanding components.

United States Automotive Parts Die Casting Market Product Analysis

Product innovation in the US automotive parts die casting market is focused on developing lightweight, high-strength components using advanced materials and processes. This includes the adoption of innovative alloys, such as aluminum-silicon and magnesium-aluminum alloys, to enhance the mechanical properties of die castings. Technological advancements in rapid prototyping and simulation software are also improving design efficiency and reducing lead times. The market is witnessing a growing demand for complex geometries and surface finishes, requiring advanced die casting technologies and skilled labor. The competitive advantage lies in delivering high-quality, cost-effective components that meet stringent automotive standards.

Key Drivers, Barriers & Challenges in United States Automotive Parts Die Casting Market

Key Drivers: The primary drivers include the increasing demand for lightweight vehicles to improve fuel efficiency and reduce emissions, coupled with advancements in die casting technologies leading to higher precision and automation. Government regulations promoting sustainable manufacturing practices further incentivize the adoption of lightweight materials and efficient processes. The growing popularity of electric vehicles also significantly boosts demand for specialized die-cast components.

Challenges: Significant challenges include fluctuating raw material prices, particularly for aluminum and magnesium, impacting production costs. Supply chain disruptions can lead to production delays and increased expenses. Furthermore, stringent environmental regulations regarding emissions and waste disposal necessitate significant investments in pollution control equipment. Intense competition from alternative manufacturing processes also presents a challenge to market growth. The impact of these challenges can amount to a xx% reduction in projected market growth, as per our estimations.

Growth Drivers in the United States Automotive Parts Die Casting Market Market

Growth is primarily fueled by rising demand for lightweight vehicles and technological advancements in die casting. Government incentives for fuel-efficient vehicles and stricter emission standards further accelerate market growth.

Challenges Impacting United States Automotive Parts Die Casting Market Growth

Raw material price volatility, supply chain disruptions, and stringent environmental regulations pose significant challenges. Competitive pressures from alternative manufacturing technologies also hinder market growth.

Key Players Shaping the United States Automotive Parts Die Casting Market Market

- Georg Fischer Limited

- Endurance Technologies

- Rheinmetall AG

- Bocar Group

- Ryobi Die Casting LTD

- Nemak

- Form Technologies In

- Shiloh Industries

- Rockman Industries

Significant United States Automotive Parts Die Casting Market Industry Milestones

- 2021: Introduction of a new high-pressure die casting machine by a major player, enhancing production efficiency.

- 2022: Successful merger between two key players, leading to increased market consolidation.

- 2023: Launch of a new lightweight aluminum alloy specifically designed for automotive applications.

- 2024: Implementation of stricter environmental regulations impacting waste management practices.

Future Outlook for United States Automotive Parts Die Casting Market Market

The US automotive parts die casting market is poised for continued growth, driven by the ongoing demand for lightweight vehicles and the adoption of advanced die casting technologies. Strategic investments in automation and the development of sustainable materials will be crucial for success. The market presents significant opportunities for companies that can offer innovative solutions that meet the evolving needs of the automotive industry. The projected market size is expected to reach xx Million by 2033, representing a substantial expansion of the market.

United States Automotive Parts Die Casting Market Segmentation

-

1. Process

- 1.1. Pressure Die Casting

- 1.2. Vacuum Die Casting

- 1.3. Squeeze Die Casting

- 1.4. Others

-

2. Raw Material

- 2.1. Aluminium

- 2.2. Magnesium

- 2.3. Zinc

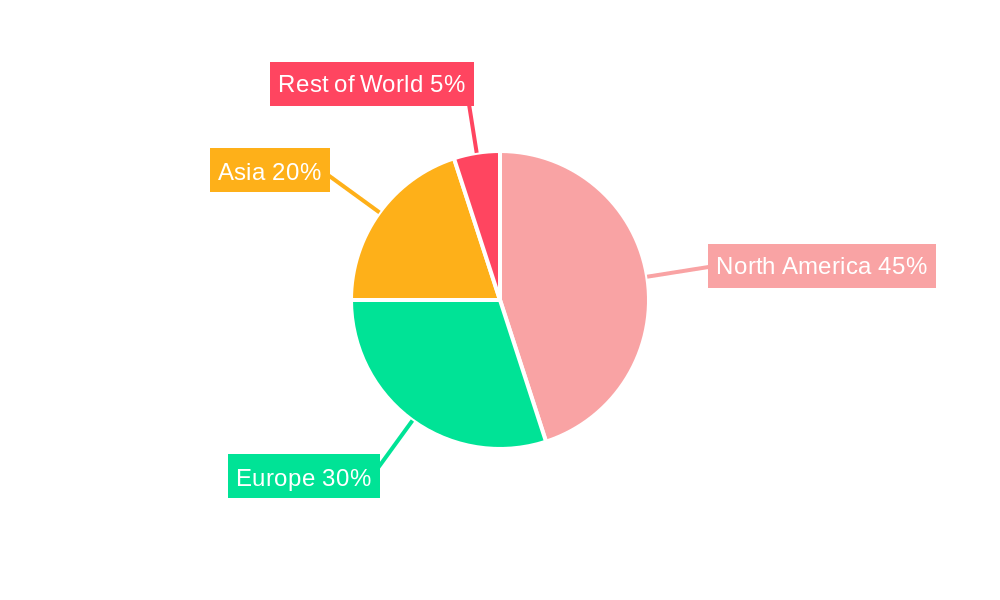

United States Automotive Parts Die Casting Market Segmentation By Geography

- 1. United States

United States Automotive Parts Die Casting Market Regional Market Share

Geographic Coverage of United States Automotive Parts Die Casting Market

United States Automotive Parts Die Casting Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 4.7% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Surge in Trend of Yacht Tourism

- 3.3. Market Restrains

- 3.3.1. Higher Rentals During Peak Season

- 3.4. Market Trends

- 3.4.1. Cost Issues and Resource Inefficiencies

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. United States Automotive Parts Die Casting Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Process

- 5.1.1. Pressure Die Casting

- 5.1.2. Vacuum Die Casting

- 5.1.3. Squeeze Die Casting

- 5.1.4. Others

- 5.2. Market Analysis, Insights and Forecast - by Raw Material

- 5.2.1. Aluminium

- 5.2.2. Magnesium

- 5.2.3. Zinc

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. United States

- 5.1. Market Analysis, Insights and Forecast - by Process

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Georg Fischer Limited

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Endurance Technologies

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Rheinmetall AG

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Bocar Group

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Ryobi Die Casting LTD*List Not Exhaustive

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Nemak

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Form Technologies In

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Shiloh Industries

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Rockman Industries

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.1 Georg Fischer Limited

List of Figures

- Figure 1: United States Automotive Parts Die Casting Market Revenue Breakdown (million, %) by Product 2025 & 2033

- Figure 2: United States Automotive Parts Die Casting Market Share (%) by Company 2025

List of Tables

- Table 1: United States Automotive Parts Die Casting Market Revenue million Forecast, by Process 2020 & 2033

- Table 2: United States Automotive Parts Die Casting Market Revenue million Forecast, by Raw Material 2020 & 2033

- Table 3: United States Automotive Parts Die Casting Market Revenue million Forecast, by Region 2020 & 2033

- Table 4: United States Automotive Parts Die Casting Market Revenue million Forecast, by Process 2020 & 2033

- Table 5: United States Automotive Parts Die Casting Market Revenue million Forecast, by Raw Material 2020 & 2033

- Table 6: United States Automotive Parts Die Casting Market Revenue million Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the United States Automotive Parts Die Casting Market?

The projected CAGR is approximately 4.7%.

2. Which companies are prominent players in the United States Automotive Parts Die Casting Market?

Key companies in the market include Georg Fischer Limited, Endurance Technologies, Rheinmetall AG, Bocar Group, Ryobi Die Casting LTD*List Not Exhaustive, Nemak, Form Technologies In, Shiloh Industries, Rockman Industries.

3. What are the main segments of the United States Automotive Parts Die Casting Market?

The market segments include Process, Raw Material.

4. Can you provide details about the market size?

The market size is estimated to be USD 3580.4 million as of 2022.

5. What are some drivers contributing to market growth?

Surge in Trend of Yacht Tourism.

6. What are the notable trends driving market growth?

Cost Issues and Resource Inefficiencies.

7. Are there any restraints impacting market growth?

Higher Rentals During Peak Season.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "United States Automotive Parts Die Casting Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the United States Automotive Parts Die Casting Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the United States Automotive Parts Die Casting Market?

To stay informed about further developments, trends, and reports in the United States Automotive Parts Die Casting Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

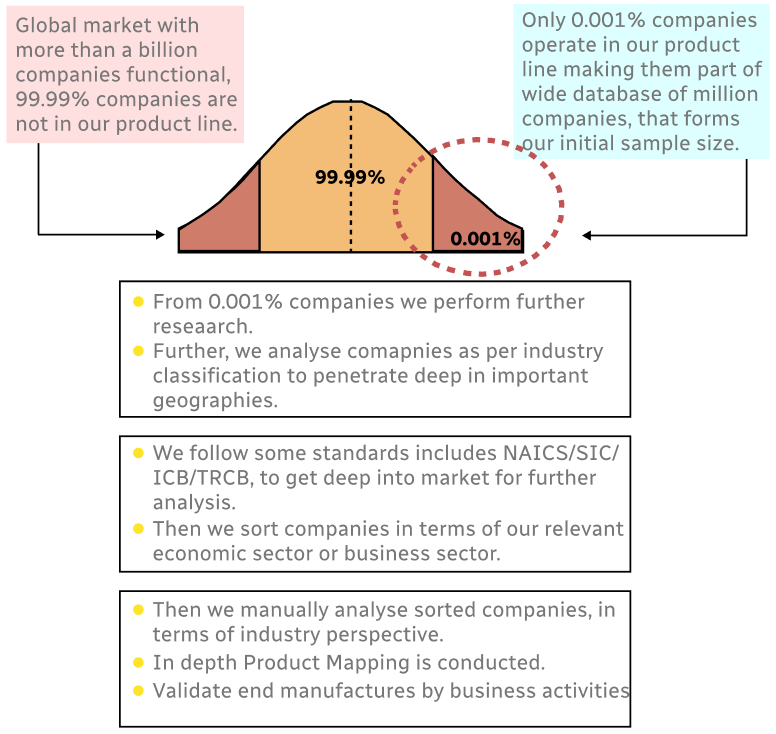

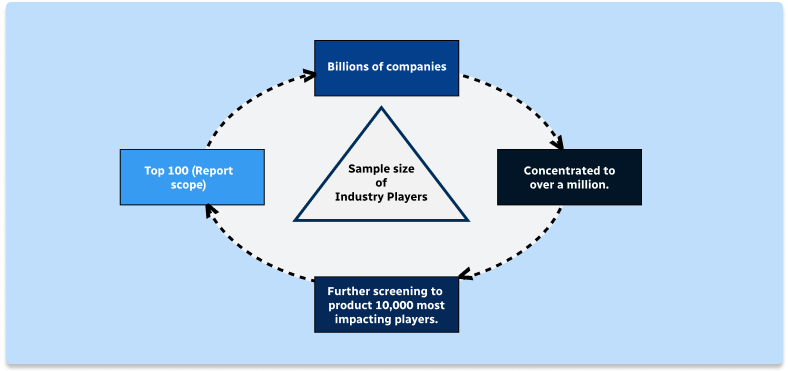

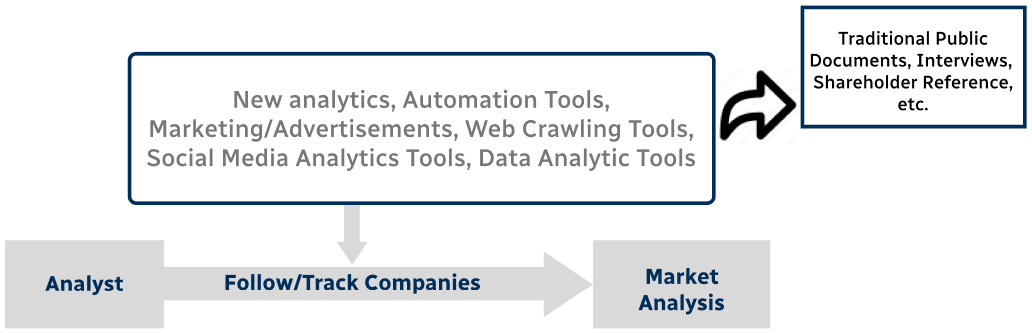

Step 1 - Identification of Relevant Samples Size from Population Database

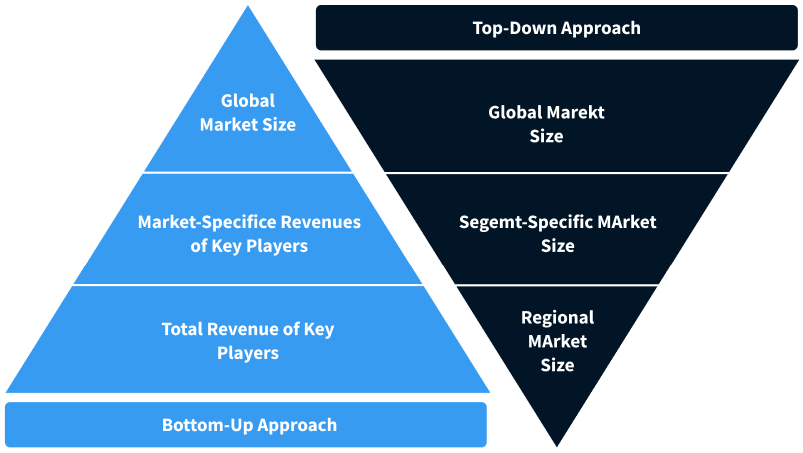

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence