Key Insights

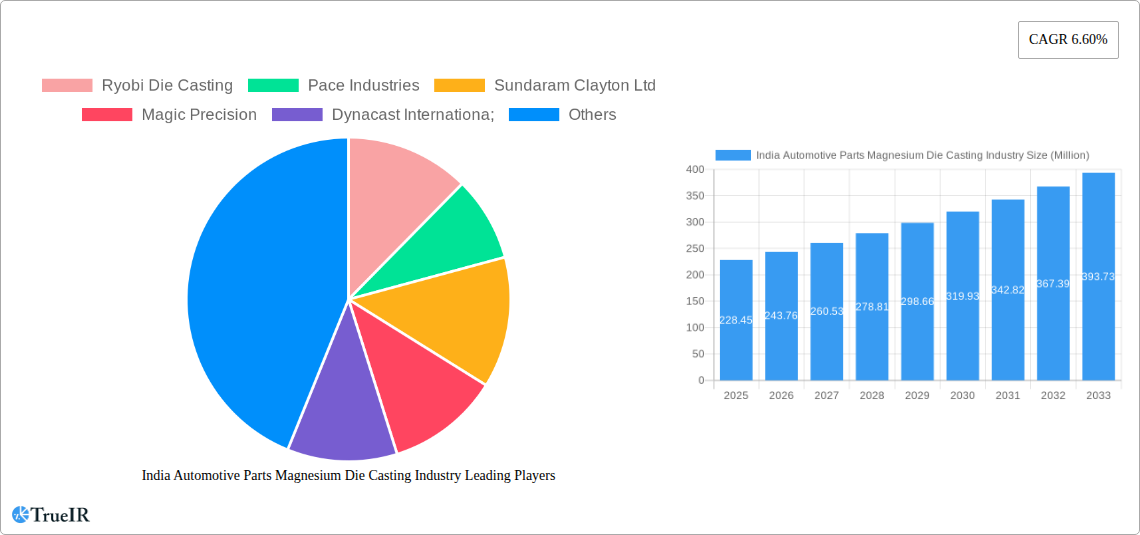

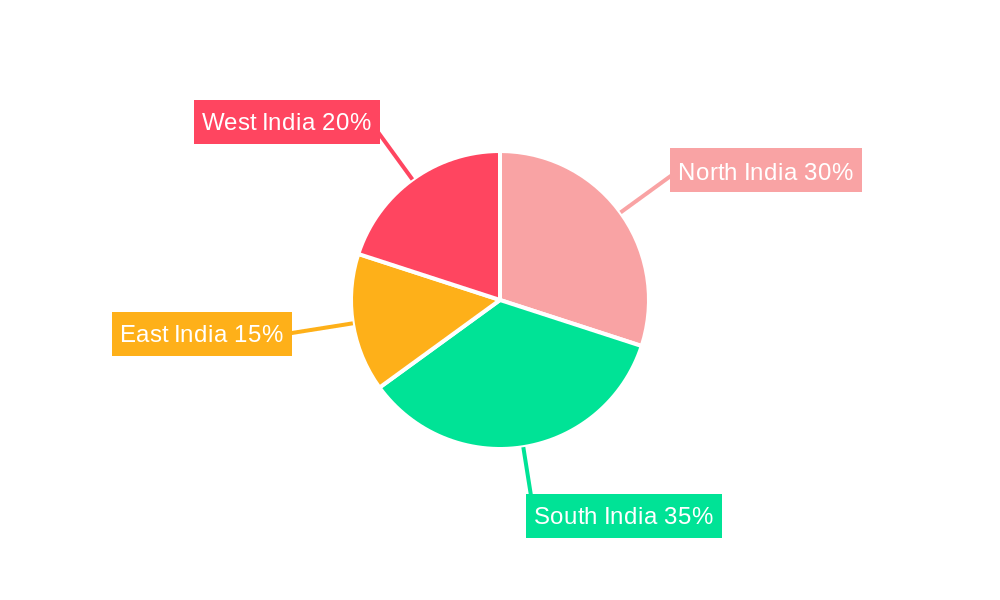

The India automotive parts magnesium die casting market is experiencing robust growth, projected to reach $228.45 million in 2025 and exhibiting a Compound Annual Growth Rate (CAGR) of 6.60% from 2025 to 2033. This expansion is driven by the increasing demand for lightweight vehicles to enhance fuel efficiency and reduce emissions, aligning with global sustainability initiatives. The automotive industry's shift towards electric vehicles (EVs) further fuels this demand, as magnesium's lightweight properties are crucial for extending EV battery range. Key applications include body assemblies, engine parts, and transmission components, with pressure die casting being the dominant production process. Growth is also spurred by advancements in die casting technology, leading to improved casting quality and reduced production costs. However, the market faces challenges including the relatively high cost of magnesium compared to aluminum and the complexity involved in magnesium die casting, requiring specialized expertise and equipment. The market's segmentation by production process (pressure die casting, vacuum die casting, squeeze die casting, semi-solid die casting) and application type (body assemblies, engine parts, transmission parts, other applications) provides insights into specific growth areas and potential investment opportunities. Regional variations exist across North, South, East, and West India, reflecting differences in manufacturing hubs and automotive production clusters. Leading players like Ryobi Die Casting, Pace Industries, and Sundaram Clayton Ltd are actively shaping the market landscape through technological innovation and strategic partnerships.

India Automotive Parts Magnesium Die Casting Industry Market Size (In Million)

The forecast period of 2025-2033 anticipates continued growth, driven by India's burgeoning automotive sector and government initiatives promoting domestic manufacturing. Increased adoption of advanced driver-assistance systems (ADAS) and the integration of lightweight components in these systems further contribute to market expansion. The competitive landscape features both domestic and international players, leading to strategic alliances and technological collaborations. While challenges remain, the overall outlook for the India automotive parts magnesium die casting market remains positive, fueled by a strong growth trajectory and increasing demand for lightweight and fuel-efficient vehicles. Further research into specific regional trends and technological advancements will provide a more granular understanding of market dynamics.

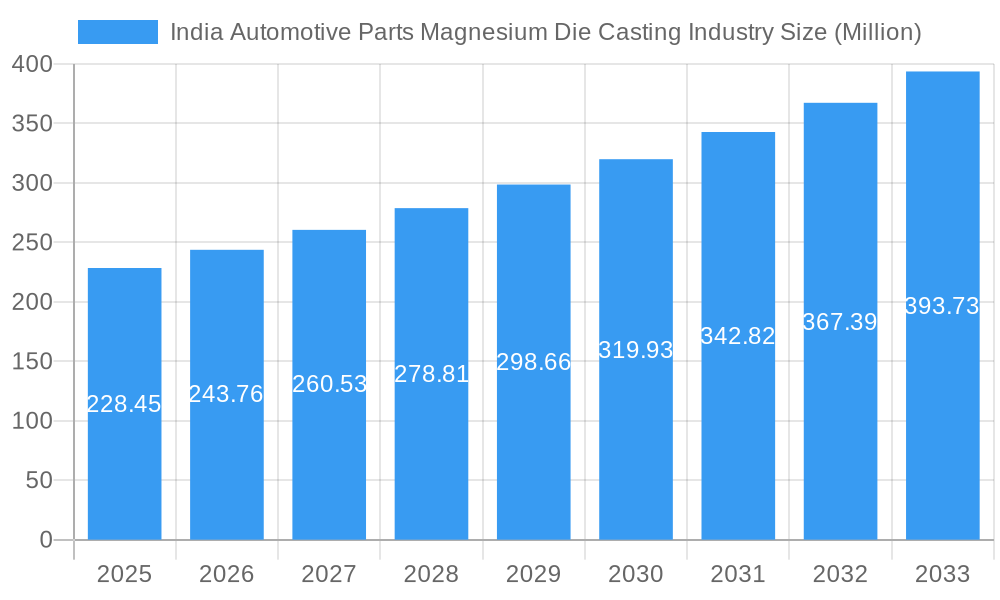

India Automotive Parts Magnesium Die Casting Industry Company Market Share

India Automotive Parts Magnesium Die Casting Industry: A Comprehensive Market Report (2019-2033)

This dynamic report provides a deep dive into the burgeoning India Automotive Parts Magnesium Die Casting Industry, offering invaluable insights for stakeholders across the value chain. Leveraging extensive market research and data analysis spanning the period 2019-2033 (Study Period), with a focus on 2025 (Base Year and Estimated Year), and forecasting to 2033 (Forecast Period), this report unveils the market's structure, competitive landscape, growth drivers, challenges, and future outlook. The historical period covered is 2019-2024. Expect detailed analysis of market size (in Millions), CAGR, and key segments, empowering informed decision-making.

India Automotive Parts Magnesium Die Casting Industry Market Structure & Competitive Landscape

The Indian automotive parts magnesium die casting market exhibits a moderately concentrated structure, with a few large players and numerous smaller entities. The Herfindahl-Hirschman Index (HHI) for 2024 is estimated at xx, indicating a moderately concentrated market. Innovation is a key driver, particularly in developing lightweight and high-strength magnesium alloys for electric vehicle (EV) components. Stringent emission norms and fuel efficiency standards from the Indian government are significantly impacting the market, driving demand for lightweight materials. Substitute materials like aluminum and plastics pose a competitive threat, although magnesium's unique properties in terms of strength-to-weight ratio remain advantageous. The end-user segmentation is primarily driven by the passenger car and commercial vehicle sectors. M&A activity has been moderate in recent years, with approximately xx deals recorded between 2019 and 2024, totaling an estimated value of xx Million. Key trends include strategic partnerships to enhance technological capabilities and expand market reach.

- Market Concentration: HHI (2024): xx

- Innovation Drivers: Lightweighting, EV adoption, improved alloys.

- Regulatory Impacts: Stringent emission norms, fuel efficiency standards.

- Product Substitutes: Aluminum, plastics.

- End-User Segmentation: Passenger cars, commercial vehicles.

- M&A Trends: xx deals (2019-2024), estimated value xx Million.

India Automotive Parts Magnesium Die Casting Industry Market Trends & Opportunities

The Indian automotive parts magnesium die casting market is experiencing robust growth, driven by the expanding automotive sector, increasing demand for lightweight vehicles, and rising adoption of EVs. The market size was estimated at xx Million in 2024 and is projected to reach xx Million by 2033, exhibiting a CAGR of xx% during the forecast period. Technological advancements, such as the introduction of high-pressure die casting machines and improved alloy formulations, are enhancing the efficiency and quality of magnesium die castings. Consumer preference for fuel-efficient and environmentally friendly vehicles is fueling demand for lightweight materials. Intense competition is pushing companies to innovate and offer competitive pricing and superior quality. Market penetration rates for magnesium die castings in various automotive applications are expected to increase significantly, particularly in body assemblies and engine parts.

Dominant Markets & Segments in India Automotive Parts Magnesium Die Casting Industry

The Indian automotive parts magnesium die casting industry is experiencing significant growth, driven by the nation's expanding automotive manufacturing sector and a strong push towards lightweighting. While specific regional data is still evolving, market concentration is anticipated in established automotive manufacturing hubs across India, including regions with a high density of Original Equipment Manufacturers (OEMs) and their supply chains. Within the production process segment, pressure die casting remains the dominant method, owing to its inherent cost-effectiveness, exceptional efficiency for high-volume production, and its ability to produce intricate components with high precision. However, emerging techniques such as semi-solid die casting are steadily gaining traction. This is attributed to their superior capability in manufacturing complex automotive parts that demand exceptional surface finish and intricate geometries, often surpassing the limitations of traditional pressure die casting.

In terms of application type, body assemblies and engine parts stand out as major consumers of magnesium die castings. This surge in demand is primarily fueled by the automotive industry's unwavering focus on vehicle lightweighting to enhance fuel efficiency, reduce emissions, and improve overall vehicle performance. The strategic use of magnesium in these critical areas directly contributes to achieving these paramount objectives.

-

Key Growth Drivers:

- Surging Automotive Production: India's robust growth in domestic and export automotive production directly translates to higher demand for automotive components.

- Intensified Demand for Lightweight Vehicles: The persistent global and domestic trend towards lightweight vehicles to improve fuel economy and performance is a primary catalyst.

- Accelerated Electric Vehicle (EV) Adoption: The rapid growth of the EV market necessitates lightweight components to maximize range and battery efficiency.

- Proactive Government Initiatives: Government policies and incentives promoting fuel efficiency, emission reduction, and the adoption of advanced manufacturing technologies are playing a crucial role.

- Continuous Technological Advancements: Ongoing innovation in magnesium alloys, die casting machinery, and process optimization are enhancing the competitiveness and applicability of magnesium die castings.

-

Dominant Segments:

- Production Process Type: Pressure Die Casting (continues to dominate due to cost and volume)

- Application Type: Body Assemblies, Engine Parts (critical for lightweighting and performance enhancement)

India Automotive Parts Magnesium Die Casting Industry Product Analysis

The product landscape within the India Automotive Parts Magnesium Die Casting Industry is characterized by continuous innovation and a growing emphasis on high-performance materials. Recent advancements have seen the development of advanced magnesium alloys that offer significantly enhanced properties. These include improved tensile strength, superior fatigue resistance, and enhanced corrosion resistance, making them increasingly competitive against traditional materials like aluminum and even steel in certain applications. Furthermore, sophisticated die-casting processes, including advanced cooling systems and precise mold designs, are enabling the production of thinner-walled, more complex, and structurally integral magnesium components.

These technological strides directly translate to improved part performance, extended durability, and a reduced environmental footprint throughout the product lifecycle. The market fit for magnesium die castings is exceptionally strong, particularly in automotive applications where a synergistic combination of extreme lightweighting, high structural integrity, and superior stiffness is paramount. The ongoing evolution of casting technologies is not only refining existing applications but also unlocking new possibilities for magnesium's integration into next-generation automotive designs, from structural components to intricate interior and exterior parts.

Key Drivers, Barriers & Challenges in India Automotive Parts Magnesium Die Casting Industry

Key Drivers: The India Automotive Parts Magnesium Die Casting Industry is propelled by several powerful forces. The relentless pursuit of lightweight vehicles to boost fuel efficiency and reduce emissions remains a primary driver. The burgeoning adoption of Electric Vehicles (EVs), where weight reduction is critical for maximizing range, further accelerates this demand. Supportive government initiatives aimed at enhancing fuel efficiency standards and promoting sustainable automotive practices also play a significant role. Complementing these are rapid technological advancements in die casting machinery, automation, and the development of specialized magnesium alloys, which are making these components more accessible and performant.

Barriers & Challenges: Despite the positive outlook, certain hurdles need to be navigated. The inherent volatility and cost of raw magnesium, subject to global market fluctuations, can impact manufacturing costs. Supply chain disruptions, both for raw materials and finished components, can lead to production delays. The relatively high initial investment in specialized die casting equipment and tooling, compared to some alternative materials, can be a barrier for smaller manufacturers. Furthermore, the need for specialized expertise in handling magnesium and operating advanced die casting machinery requires significant investment in training and skill development, potentially limiting wider adoption across the industry.

Growth Drivers in the India Automotive Parts Magnesium Die Casting Industry Market

The expanding Indian automotive sector, increasing demand for fuel-efficient vehicles, and rising EV adoption are key drivers. Government initiatives supporting the use of lightweight materials further propel market growth. Technological innovations in die casting processes are continuously improving efficiency and product quality.

Challenges Impacting India Automotive Parts Magnesium Die Casting Industry Growth

The growth trajectory of the India Automotive Parts Magnesium Die Casting Industry faces several notable challenges. The fluctuating prices of raw magnesium, often linked to global supply and demand dynamics, present a significant concern for cost predictability and profitability. Potential supply chain constraints for both raw materials and specialized tooling can lead to production bottlenecks and delivery delays, impacting the reliability of supply for automotive OEMs. The comparatively higher production costs associated with magnesium die casting, particularly when compared to high-volume aluminum casting, can pose a barrier to wider adoption, especially in cost-sensitive vehicle segments.

Furthermore, the competitive landscape from other lightweight materials, most notably aluminum, demands continuous innovation and cost optimization from magnesium die casters. Effectively communicating the unique advantages of magnesium, such as its superior stiffness-to-weight ratio and excellent damping properties, while simultaneously addressing cost perceptions, is crucial for sustained market penetration and growth.

Key Players Shaping the India Automotive Parts Magnesium Die Casting Industry Market

The Indian automotive parts magnesium die casting sector is a dynamic landscape shaped by both established global players and emerging domestic manufacturers. These companies are instrumental in driving innovation, expanding production capacities, and catering to the evolving needs of the automotive industry. Key entities contributing to the market's growth include:

- Ryobi Die Casting

- Pace Industries

- Sundaram Clayton Ltd

- Magic Precision

- Dynacast International

- Shiloh Industries Inc

- George Fischer Ltd (GF)

- JPM Group

- Meridian Lightweight Technologies Inc

- Sandhar Group

Significant India Automotive Parts Magnesium Die Casting Industry Industry Milestones

- May 2022: GF Casting Solutions announced turnkey solutions for automotive complex issues, focusing on electric drive and lightweight structural parts.

- January 2022: Bühler Group launched the "Carat 560 SM" magnesium die-casting machine for high-volume, lightweight automotive part production.

Future Outlook for India Automotive Parts Magnesium Die Casting Industry Market

The Indian automotive parts magnesium die casting industry is poised for sustained growth, driven by the continued expansion of the automotive sector, government support for lightweighting, and the rising adoption of EVs. Strategic partnerships and technological advancements will further shape the market landscape, creating significant opportunities for growth and innovation in the coming years.

India Automotive Parts Magnesium Die Casting Industry Segmentation

-

1. Production Process Type

- 1.1. Pressure Die Casting

- 1.2. Vacuum Die Cating

- 1.3. Squeeze Die Casting

- 1.4. Semi-Solid Die Casting

-

2. Application Type

- 2.1. Body Assemblies

- 2.2. Engine Parts

- 2.3. Transmission Parts

- 2.4. Other Applications

India Automotive Parts Magnesium Die Casting Industry Segmentation By Geography

- 1. India

India Automotive Parts Magnesium Die Casting Industry Regional Market Share

Geographic Coverage of India Automotive Parts Magnesium Die Casting Industry

India Automotive Parts Magnesium Die Casting Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 6.60% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Favorable Properties of Magnesium Led to Increased Adoption in Automobile Sector; Others

- 3.3. Market Restrains

- 3.3.1. Cost and Innovation in Alternate Production Processes; Others

- 3.4. Market Trends

- 3.4.1. Increasing automobile sales will help the market grow

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. India Automotive Parts Magnesium Die Casting Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 5.1.1. Pressure Die Casting

- 5.1.2. Vacuum Die Cating

- 5.1.3. Squeeze Die Casting

- 5.1.4. Semi-Solid Die Casting

- 5.2. Market Analysis, Insights and Forecast - by Application Type

- 5.2.1. Body Assemblies

- 5.2.2. Engine Parts

- 5.2.3. Transmission Parts

- 5.2.4. Other Applications

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. India

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Ryobi Die Casting

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Pace Industries

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Sundaram Clayton Ltd

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Magic Precision

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Dynacast Internationa;

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Shiloh Industries Inc

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 George Fischer Ltd *List Not Exhaustive

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 JPM Group

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Meridian Lightweight Technologies Inc

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Sandhar Group

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.1 Ryobi Die Casting

List of Figures

- Figure 1: India Automotive Parts Magnesium Die Casting Industry Revenue Breakdown (Million, %) by Product 2025 & 2033

- Figure 2: India Automotive Parts Magnesium Die Casting Industry Share (%) by Company 2025

List of Tables

- Table 1: India Automotive Parts Magnesium Die Casting Industry Revenue Million Forecast, by Production Process Type 2020 & 2033

- Table 2: India Automotive Parts Magnesium Die Casting Industry Revenue Million Forecast, by Application Type 2020 & 2033

- Table 3: India Automotive Parts Magnesium Die Casting Industry Revenue Million Forecast, by Region 2020 & 2033

- Table 4: India Automotive Parts Magnesium Die Casting Industry Revenue Million Forecast, by Production Process Type 2020 & 2033

- Table 5: India Automotive Parts Magnesium Die Casting Industry Revenue Million Forecast, by Application Type 2020 & 2033

- Table 6: India Automotive Parts Magnesium Die Casting Industry Revenue Million Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the India Automotive Parts Magnesium Die Casting Industry?

The projected CAGR is approximately 6.60%.

2. Which companies are prominent players in the India Automotive Parts Magnesium Die Casting Industry?

Key companies in the market include Ryobi Die Casting, Pace Industries, Sundaram Clayton Ltd, Magic Precision, Dynacast Internationa;, Shiloh Industries Inc, George Fischer Ltd *List Not Exhaustive, JPM Group, Meridian Lightweight Technologies Inc, Sandhar Group.

3. What are the main segments of the India Automotive Parts Magnesium Die Casting Industry?

The market segments include Production Process Type, Application Type.

4. Can you provide details about the market size?

The market size is estimated to be USD 228.45 Million as of 2022.

5. What are some drivers contributing to market growth?

Favorable Properties of Magnesium Led to Increased Adoption in Automobile Sector; Others.

6. What are the notable trends driving market growth?

Increasing automobile sales will help the market grow.

7. Are there any restraints impacting market growth?

Cost and Innovation in Alternate Production Processes; Others.

8. Can you provide examples of recent developments in the market?

May 2022: GF Casting Solutions announced turnkey solutions to the many complex issues faced by automotive, showcasing its agility with its pioneering approach to developing electric drive components as well as lightweight structural parts.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "India Automotive Parts Magnesium Die Casting Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the India Automotive Parts Magnesium Die Casting Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the India Automotive Parts Magnesium Die Casting Industry?

To stay informed about further developments, trends, and reports in the India Automotive Parts Magnesium Die Casting Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

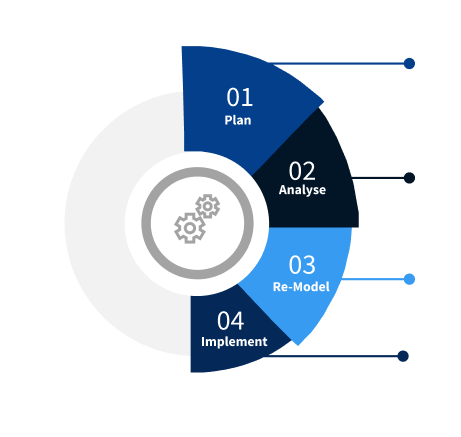

Methodology

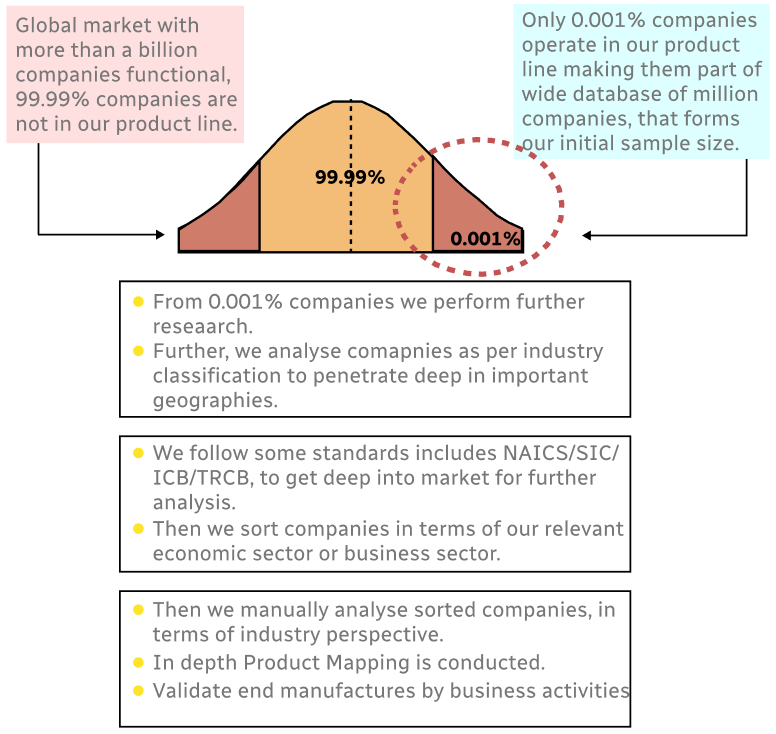

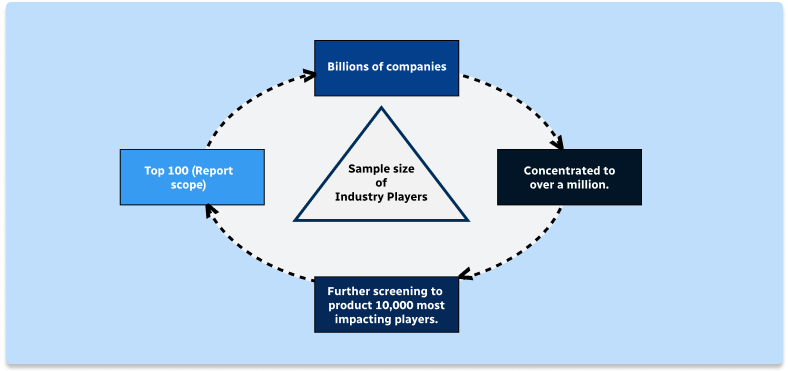

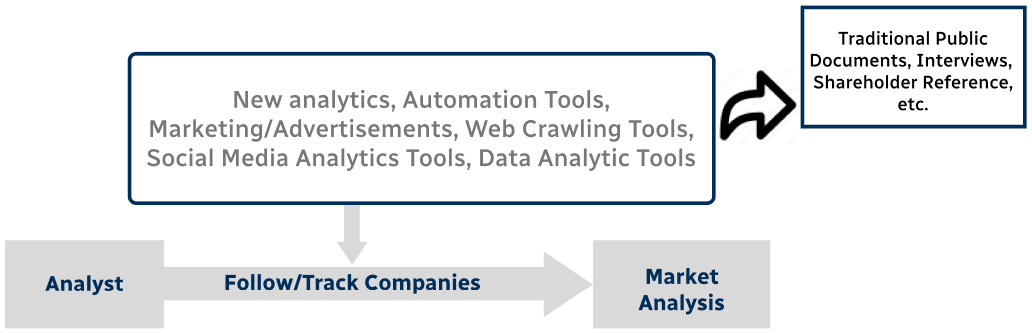

Step 1 - Identification of Relevant Samples Size from Population Database

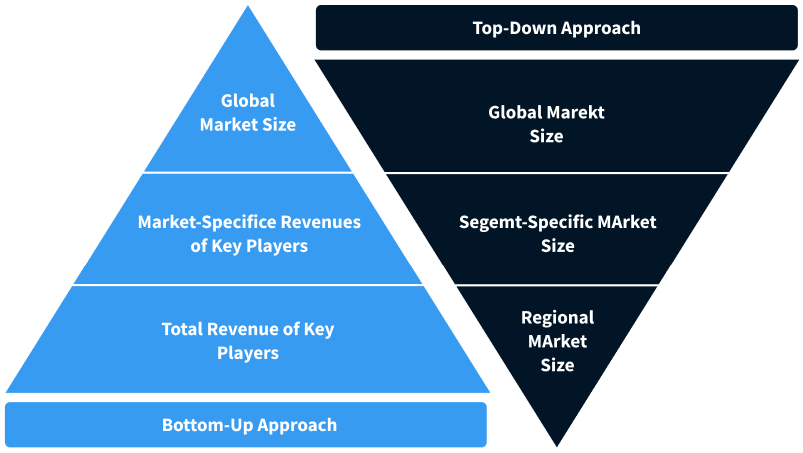

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence