Key Insights

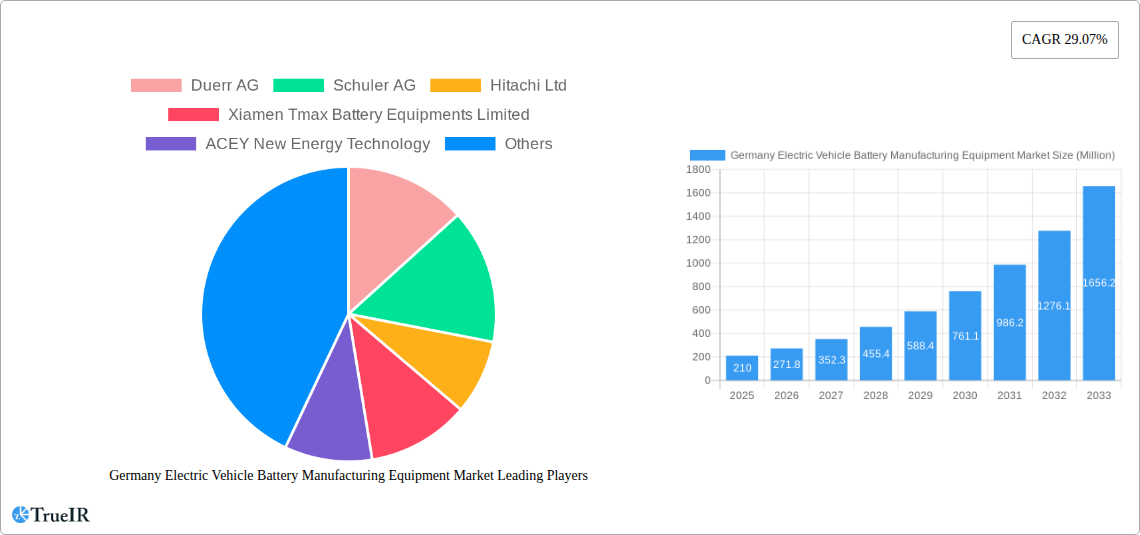

The German electric vehicle (EV) battery manufacturing equipment market is experiencing robust growth, driven by the accelerating adoption of electric vehicles within the country and the broader European Union. With a current market size of €210 million in 2025 (estimated based on the provided 0.21 value in millions), and a compound annual growth rate (CAGR) of 29.07%, the market is projected to reach significant value by 2033. This expansion is fueled by several key factors. Firstly, substantial government incentives and supportive policies aimed at promoting EV adoption are creating a favorable environment for investment in battery production. Secondly, Germany's strong automotive industry, a global leader in manufacturing and engineering, is strategically positioning itself within the EV supply chain. This involves significant investments in domestic battery cell and pack production, directly translating into a higher demand for sophisticated manufacturing equipment. Thirdly, ongoing advancements in battery technology, particularly in areas like solid-state batteries and improved energy density, are driving the need for more advanced and adaptable manufacturing equipment. Competition is fierce, with both established players like Dürr AG, Schuler AG, and Robert Bosch Manufacturing Solutions GmbH, and emerging companies like Xiamen Tmax Battery Equipments Limited vying for market share. This competitive landscape is fostering innovation and driving down costs, further stimulating market expansion.

Germany Electric Vehicle Battery Manufacturing Equipment Market Market Size (In Million)

However, challenges remain. Potential restraints on market growth include the global supply chain volatility impacting the availability of critical raw materials needed for battery production, as well as the need for significant capital investment in highly specialized equipment. The market is segmented based on equipment type (e.g., cell assembly, module assembly, pack assembly, testing equipment) and end-user (OEMs, Tier-1 suppliers), although specific segment data isn't provided. Nevertheless, the overall outlook remains strongly positive, suggesting continued robust expansion for the German EV battery manufacturing equipment market throughout the forecast period (2025-2033). The market's success will hinge on overcoming supply chain hurdles and continuing technological innovations to meet the growing demands of the EV sector.

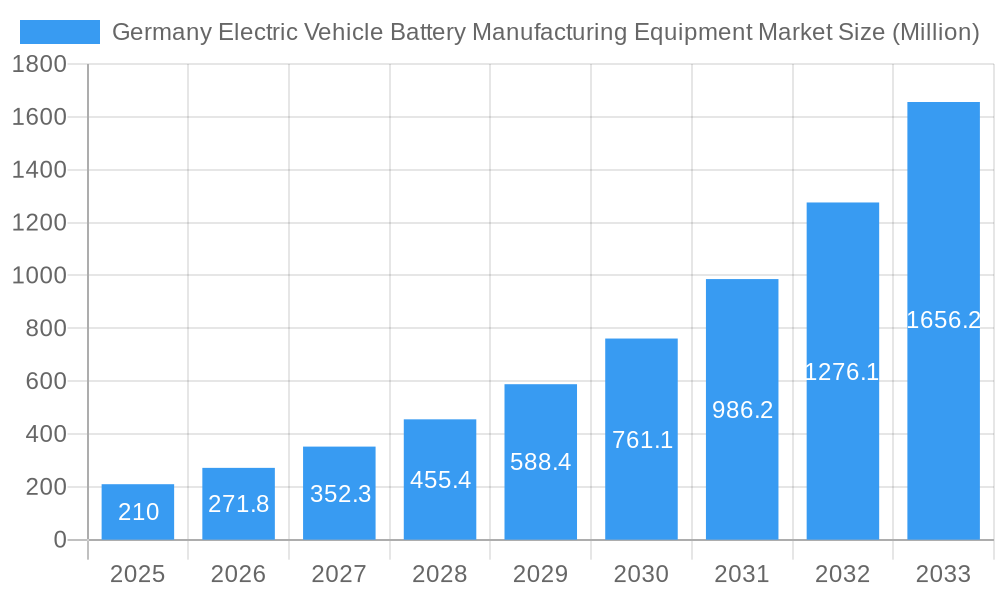

Germany Electric Vehicle Battery Manufacturing Equipment Market Company Market Share

Germany Electric Vehicle Battery Manufacturing Equipment Market: A Comprehensive Report (2019-2033)

This dynamic report provides a deep dive into the burgeoning Germany Electric Vehicle (EV) Battery Manufacturing Equipment Market, offering invaluable insights for stakeholders across the value chain. Leveraging extensive market research and data analysis spanning the period 2019-2033 (with a base year of 2025 and forecast period 2025-2033), this report illuminates key trends, growth drivers, challenges, and competitive dynamics shaping this rapidly evolving sector. The market is projected to reach xx Million by 2033, exhibiting a CAGR of xx% during the forecast period.

Germany Electric Vehicle Battery Manufacturing Equipment Market Structure & Competitive Landscape

The German EV battery manufacturing equipment market exhibits a moderately concentrated structure, with several key players holding significant market share. The Herfindahl-Hirschman Index (HHI) is estimated at xx, indicating a moderately competitive landscape. Innovation is a crucial driver, with companies continuously investing in R&D to enhance equipment efficiency, automation, and precision. Stringent environmental regulations and safety standards in Germany significantly impact the market, driving the adoption of eco-friendly and safe manufacturing technologies. The market witnesses a gradual shift toward automation and digitization, boosting productivity and reducing manufacturing costs. Product substitution is limited due to the specialized nature of the equipment, although competition exists based on price, efficiency, and technological advancements. The end-user segment comprises primarily battery cell manufacturers, battery pack assemblers, and OEMs.

- Market Concentration: Moderately Concentrated (HHI: xx)

- Innovation Drivers: Automation, AI, advanced materials processing

- Regulatory Impacts: Stringent environmental and safety regulations

- Product Substitutes: Limited, primarily based on technological features

- End-User Segmentation: Battery cell manufacturers, pack assemblers, OEMs

- M&A Trends: xx number of M&A deals recorded between 2019-2024, totaling xx Million in value.

Germany Electric Vehicle Battery Manufacturing Equipment Market Trends & Opportunities

The German EV battery manufacturing equipment market is experiencing robust growth, fueled by the increasing demand for electric vehicles and government initiatives promoting EV adoption. The market size is estimated at xx Million in 2025 and is projected to reach xx Million by 2033, driven by a CAGR of xx%. Technological advancements such as automation, artificial intelligence (AI), and the adoption of advanced materials are revolutionizing the manufacturing process, leading to increased efficiency and productivity. Consumer preference for EVs is steadily rising, supported by growing environmental awareness and decreasing battery costs. The competitive landscape is characterized by both established players and new entrants vying for market share, stimulating innovation and price competitiveness. Market penetration rates for advanced equipment are projected to increase significantly over the forecast period, driven by factors such as government incentives and the need for high-volume battery production.

Dominant Markets & Segments in Germany Electric Vehicle Battery Manufacturing Equipment Market

The dominant segment within the German EV battery manufacturing equipment market is the [Specify dominant segment, e.g., automation equipment]. This segment's dominance is driven by several key factors:

- Growth Drivers:

- Increasing demand for high-volume battery production

- Government incentives and subsidies for EV manufacturing

- Focus on improving production efficiency and reducing costs

- Technological advancements in automation and robotics

Germany is the leading market within the country, driven by its strong automotive industry and supportive government policies. The strong presence of major automotive OEMs and battery cell manufacturers within Germany creates a significant demand for advanced manufacturing equipment. The favorable regulatory environment and robust infrastructure further contribute to the market's dominance.

Germany Electric Vehicle Battery Manufacturing Equipment Market Product Analysis

The market offers a wide range of equipment, including cell assembly lines, electrode coating systems, material handling robots, and testing equipment. Recent innovations focus on increasing throughput, improving precision, and reducing manufacturing costs. The competitive advantage stems from factors such as automation levels, precision, integration capabilities, and after-sales service. Advanced features like AI-powered process optimization are gaining traction, while equipment incorporating sustainable materials and processes are increasingly demanded.

Key Drivers, Barriers & Challenges in Germany Electric Vehicle Battery Manufacturing Equipment Market

Key Drivers:

The market is primarily driven by the accelerating adoption of electric vehicles, fueled by environmental concerns and supportive government policies like subsidies and tax incentives. Technological advancements, particularly in automation and AI, are significantly improving manufacturing efficiency and productivity. Growing investments in domestic battery production capacity further bolster market expansion.

Challenges & Restraints:

High initial investment costs for advanced equipment pose a barrier for smaller manufacturers. Supply chain disruptions, particularly concerning raw materials and components, can impact production timelines and costs. Intense competition and pricing pressures from international players also present challenges for market participants. The complex regulatory landscape surrounding battery manufacturing also demands continuous adaptation and compliance.

Growth Drivers in the Germany Electric Vehicle Battery Manufacturing Equipment Market Market

The burgeoning EV market in Germany, coupled with government incentives aimed at boosting domestic battery production, are primary growth drivers. Technological innovations focused on automation and efficiency improvements within manufacturing processes represent another significant factor. Furthermore, a supportive regulatory environment and the presence of major automotive manufacturers drive substantial demand.

Challenges Impacting Germany Electric Vehicle Battery Manufacturing Equipment Market Growth

Competition from established international players poses a significant challenge, creating pricing pressures. Supply chain vulnerabilities, particularly for critical raw materials, create uncertainty in production. Regulatory compliance, encompassing environmental and safety standards, requires significant investment and adherence to stringent processes.

Key Players Shaping the Germany Electric Vehicle Battery Manufacturing Equipment Market Market

- Duerr AG

- Schuler AG

- Hitachi Ltd

- Xiamen Tmax Battery Equipments Limited

- ACEY New Energy Technology

- IPG Photonics Corporation

- Wuxi Lead Intelligent Equipment Co Ltd

- Targray Technology International Inc

- Xiamen Lith Machine Limited

- Robert Bosch Manufacturing Solutions GmbH

Significant Germany Electric Vehicle Battery Manufacturing Equipment Market Industry Milestones

- July 2023 & February 2024: Epsilon Advanced Materials (EAM)'s acquisition of a lithium-ion phosphate (LFP) cathode active material technology center in Moosburg, Germany, signals a significant shift in the European LFP cathode material landscape and indirectly influences equipment demand. The planned Indian facility (operational by 2025, reaching 100,000 tons capacity by 2030) will likely impact the longer-term dynamics of the German market by shifting some manufacturing processes to India.

Future Outlook for Germany Electric Vehicle Battery Manufacturing Equipment Market Market

The future of the German EV battery manufacturing equipment market appears bright, driven by continuous growth in EV sales, government support for the domestic battery industry, and ongoing technological advancements. Strategic partnerships between equipment manufacturers and battery producers are anticipated, leading to innovations in manufacturing technologies and further market expansion. The market presents significant opportunities for companies that can offer advanced, efficient, and cost-effective solutions to meet the growing demand for EV batteries.

Germany Electric Vehicle Battery Manufacturing Equipment Market Segmentation

-

1. Process

- 1.1. Mixing

- 1.2. Coating

- 1.3. Calendaring

- 1.4. Slitting and Electrode Making

- 1.5. Other Processes

-

2. Battery

- 2.1. Lithium-ion

- 2.2. Lead-acid

- 2.3. Nickel Metal Hydride Battery

- 2.4. Other Batteries

Germany Electric Vehicle Battery Manufacturing Equipment Market Segmentation By Geography

- 1. Germany

Germany Electric Vehicle Battery Manufacturing Equipment Market Regional Market Share

Geographic Coverage of Germany Electric Vehicle Battery Manufacturing Equipment Market

Germany Electric Vehicle Battery Manufacturing Equipment Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 29.07% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. 4.; Increasing Adoption of Electric Vehicles4.; Supportive Government Regulations and Policies

- 3.3. Market Restrains

- 3.3.1. 4.; Increasing Adoption of Electric Vehicles4.; Supportive Government Regulations and Policies

- 3.4. Market Trends

- 3.4.1. Increasing Adoption of Electric Vehicles

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Germany Electric Vehicle Battery Manufacturing Equipment Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Process

- 5.1.1. Mixing

- 5.1.2. Coating

- 5.1.3. Calendaring

- 5.1.4. Slitting and Electrode Making

- 5.1.5. Other Processes

- 5.2. Market Analysis, Insights and Forecast - by Battery

- 5.2.1. Lithium-ion

- 5.2.2. Lead-acid

- 5.2.3. Nickel Metal Hydride Battery

- 5.2.4. Other Batteries

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Germany

- 5.1. Market Analysis, Insights and Forecast - by Process

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Duerr AG

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Schuler AG

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Hitachi Ltd

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Xiamen Tmax Battery Equipments Limited

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 ACEY New Energy Technology

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 IPG Photonics Corporation

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Wuxi Lead Intelligent Equipment Co Ltd

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Targray Technology International Inc

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Xiamen Lith Machine Limited

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Robert Bosch Manufacturing Solutions GmbH*List Not Exhaustive 6 4 Market Ranking/Share (%) Analysis6 5 List of Other Prominent Companie

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.1 Duerr AG

List of Figures

- Figure 1: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Breakdown (Million, %) by Product 2025 & 2033

- Figure 2: Germany Electric Vehicle Battery Manufacturing Equipment Market Share (%) by Company 2025

List of Tables

- Table 1: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Million Forecast, by Region 2020 & 2033

- Table 2: Germany Electric Vehicle Battery Manufacturing Equipment Market Volume Billion Forecast, by Region 2020 & 2033

- Table 3: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Million Forecast, by Process 2020 & 2033

- Table 4: Germany Electric Vehicle Battery Manufacturing Equipment Market Volume Billion Forecast, by Process 2020 & 2033

- Table 5: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Million Forecast, by Battery 2020 & 2033

- Table 6: Germany Electric Vehicle Battery Manufacturing Equipment Market Volume Billion Forecast, by Battery 2020 & 2033

- Table 7: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Million Forecast, by Region 2020 & 2033

- Table 8: Germany Electric Vehicle Battery Manufacturing Equipment Market Volume Billion Forecast, by Region 2020 & 2033

- Table 9: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Million Forecast, by Process 2020 & 2033

- Table 10: Germany Electric Vehicle Battery Manufacturing Equipment Market Volume Billion Forecast, by Process 2020 & 2033

- Table 11: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Million Forecast, by Battery 2020 & 2033

- Table 12: Germany Electric Vehicle Battery Manufacturing Equipment Market Volume Billion Forecast, by Battery 2020 & 2033

- Table 13: Germany Electric Vehicle Battery Manufacturing Equipment Market Revenue Million Forecast, by Country 2020 & 2033

- Table 14: Germany Electric Vehicle Battery Manufacturing Equipment Market Volume Billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Germany Electric Vehicle Battery Manufacturing Equipment Market?

The projected CAGR is approximately 29.07%.

2. Which companies are prominent players in the Germany Electric Vehicle Battery Manufacturing Equipment Market?

Key companies in the market include Duerr AG, Schuler AG, Hitachi Ltd, Xiamen Tmax Battery Equipments Limited, ACEY New Energy Technology, IPG Photonics Corporation, Wuxi Lead Intelligent Equipment Co Ltd, Targray Technology International Inc, Xiamen Lith Machine Limited, Robert Bosch Manufacturing Solutions GmbH*List Not Exhaustive 6 4 Market Ranking/Share (%) Analysis6 5 List of Other Prominent Companie.

3. What are the main segments of the Germany Electric Vehicle Battery Manufacturing Equipment Market?

The market segments include Process, Battery.

4. Can you provide details about the market size?

The market size is estimated to be USD 0.21 Million as of 2022.

5. What are some drivers contributing to market growth?

4.; Increasing Adoption of Electric Vehicles4.; Supportive Government Regulations and Policies.

6. What are the notable trends driving market growth?

Increasing Adoption of Electric Vehicles.

7. Are there any restraints impacting market growth?

4.; Increasing Adoption of Electric Vehicles4.; Supportive Government Regulations and Policies.

8. Can you provide examples of recent developments in the market?

February 2024: Epsilon Advanced Materials (EAM) completed the acquisition of a lithium-ion phosphate (LFP) cathode active material technology center in Moosburg, Germany. This acquisition positions India as the first Asian country outside China to produce LFP cathode materials. EAM plans to begin constructing its facility in India in 2024, with a large-scale customer qualification plant set to be operational by 2025 and expected to reach a capacity of 100,000 tons by 2030.July 2023: Epsilon Advanced Materials (EAM) completed the acquisition of a lithium-ion phosphate (LFP) cathode active material technology center in Moosburg, Germany. This acquisition positions India as the first Asian country outside of China to produce LFP cathode materials. EAM plans to begin construction of its facility in India in 2024, with a large-scale customer qualification plant set to be operational by 2025 and expected to reach a capacity of 100,000 tons by 2030.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million and volume, measured in Billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Germany Electric Vehicle Battery Manufacturing Equipment Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Germany Electric Vehicle Battery Manufacturing Equipment Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Germany Electric Vehicle Battery Manufacturing Equipment Market?

To stay informed about further developments, trends, and reports in the Germany Electric Vehicle Battery Manufacturing Equipment Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

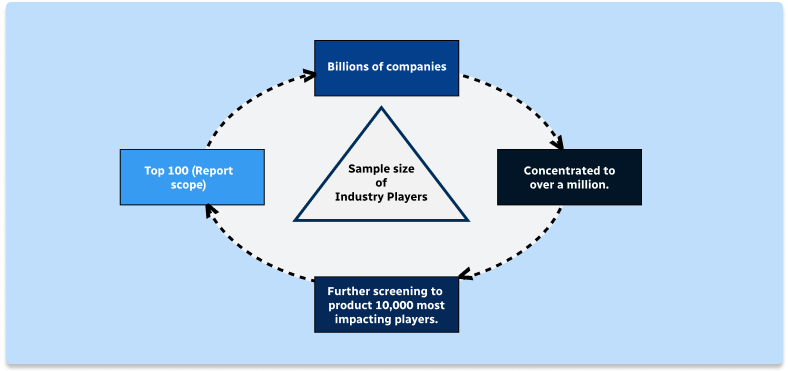

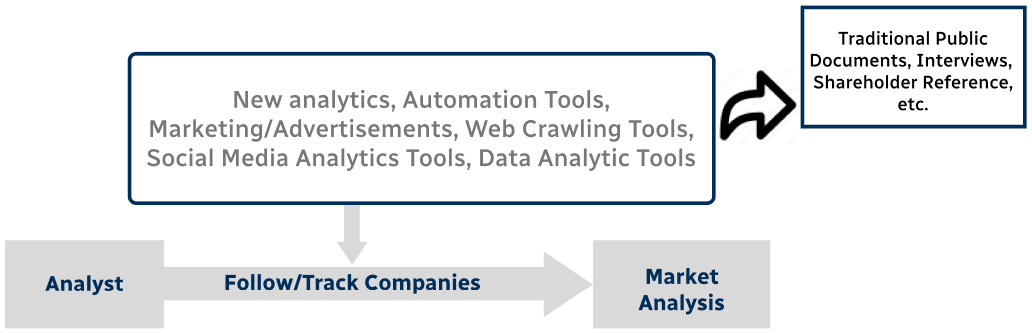

Step 1 - Identification of Relevant Samples Size from Population Database

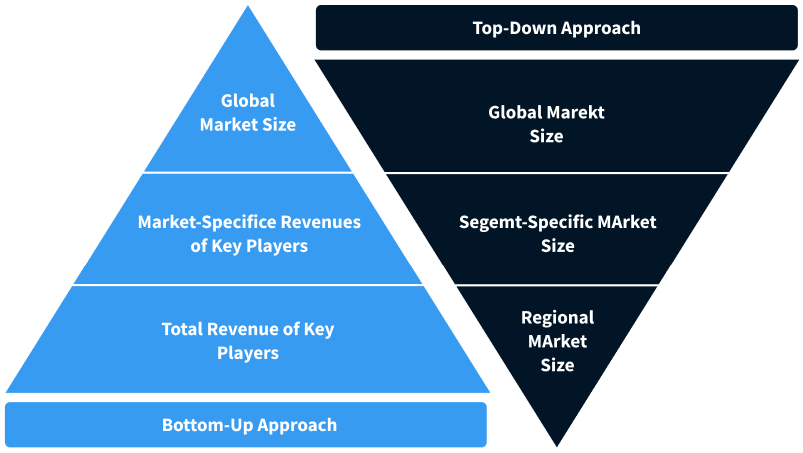

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence